China Wholesale PET Shredder Manufacturers – single screw extruder with self-cleaning filtration system – Purui

China Wholesale PET Shredder Manufacturers – single screw extruder with self-cleaning filtration system – Purui Detail:

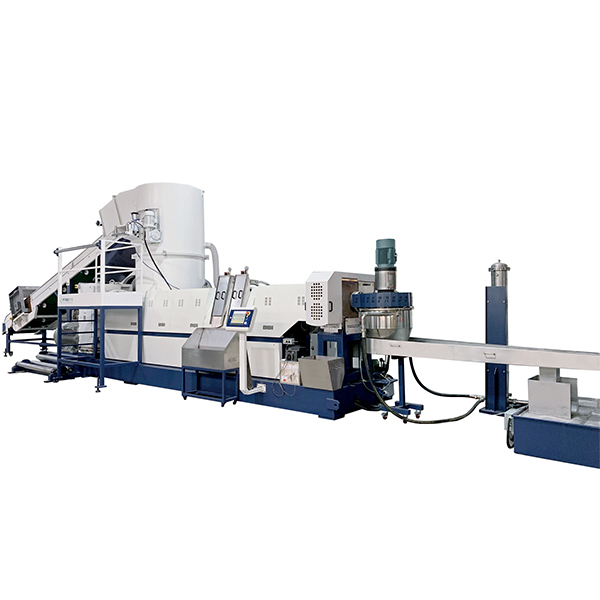

The screen changer is a manual or automatic switching device consisting of one or more filters, which is used to filter out foreign particles and impurities when plasticizing material flow filters. As we all know, the cleanliness of the recycled materials and the technological use of the final regenerated particles determine the filtration technical standards of the filtration system. For different melt filtration loads, the conventional non-stop single-plate double-station or two-piston double-station screen-changing filtration system is applied to achieve excellent melt filtration performance.

The traditional screen changer needs to replace the dirty metal filter in time, while the newest system has continuous filtering performance and automatically removes impurities on the surface of the alloy filter plate, with an effective accuracy of up to 120 mesh. The advent of the PURUI newest self-cleaning filter has realized a more efficient production of pelletizing lines with an output of more than one ton per hour.

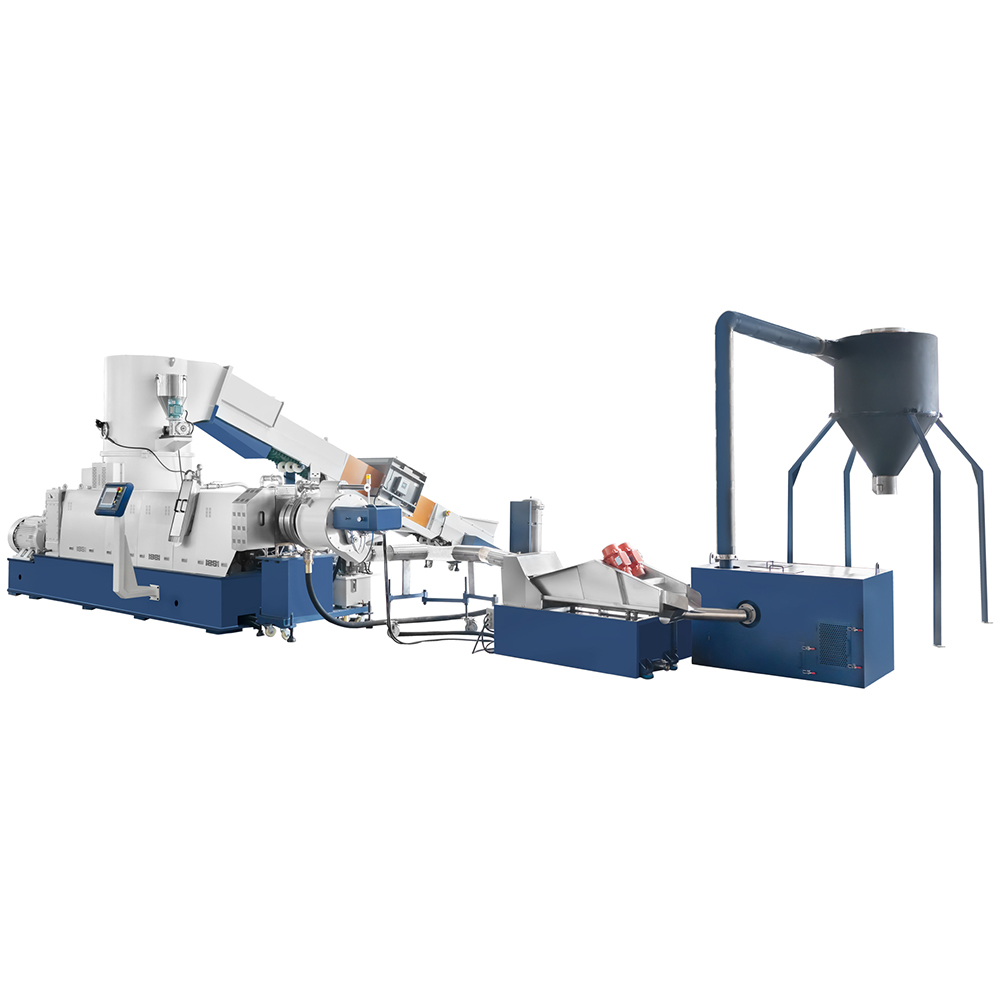

this new design equipped with compactor/cutter, single screw extruder, hot watering cutting system, self-cleaning system. which is automatic scraping action to ensure continuous self-cleaning of the filter screen, and it can reduce the waste of melt when the impurities are discharged.

Videos:

Product detail pictures:

Related Product Guide:

Sticking to the principle of "Super High-quality, Satisfactory service" ,We are striving to generally be a very good business partner of you for China Wholesale PET Shredder Manufacturers – single screw extruder with self-cleaning filtration system – Purui , The product will supply to all over the world, such as: Malawi, Finland, Atlanta, Our items are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

Lithium battery recycling equipment is a type of equipment used to recycle and recover valuable materials from lithium-ion batteries, which are commonly used in electronic devices such as smartphones, laptops, and electric vehicles. The equipment typically works by breaking down the batteries into their constituent parts, such as the cathode and anode materials, electrolyte solution, and metal foils, and then separating and purifying these materials for reuse.

There are different types of lithium battery recycling equipment available, including pyrometallurgical processes, hydrometallurgical processes, and mechanical processes. Pyrometallurgical processes involve high-temperature processing of the batteries to recover metals such as copper, nickel, and cobalt. Hydrometallurgical processes use chemical solutions to dissolve the battery components and recover metals, while mechanical processes involve shredding and milling the batteries to separate the materials.

Lithium battery recycling equipment is important for reducing the environmental impact of battery disposal and conserving resources by recovering valuable metals and materials that can be reused in new batteries or other products.

In addition to environmental and resource conservation benefits, lithium battery recycling equipment also has economic benefits. Recovering valuable metals and materials from used batteries can reduce the cost of producing new batteries, as well as create new revenue streams for companies involved in the recycling process.

Furthermore, the increasing demand for electric vehicles and other electronic devices is driving the need for a more efficient and sustainable battery recycling industry. Lithium battery recycling equipment can help meet this demand by providing a reliable and cost-effective way to recover valuable materials from used batteries.

However, it’s important to note that lithium battery recycling is still a relatively new industry, and there are challenges to overcome in terms of developing efficient and cost-effective recycling processes. Additionally, proper handling and disposal of battery waste is crucial to avoid environmental and health hazards. Therefore, proper regulations and safety measures must be in place to ensure the responsible handling and recycling of lithium batteries.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.