-

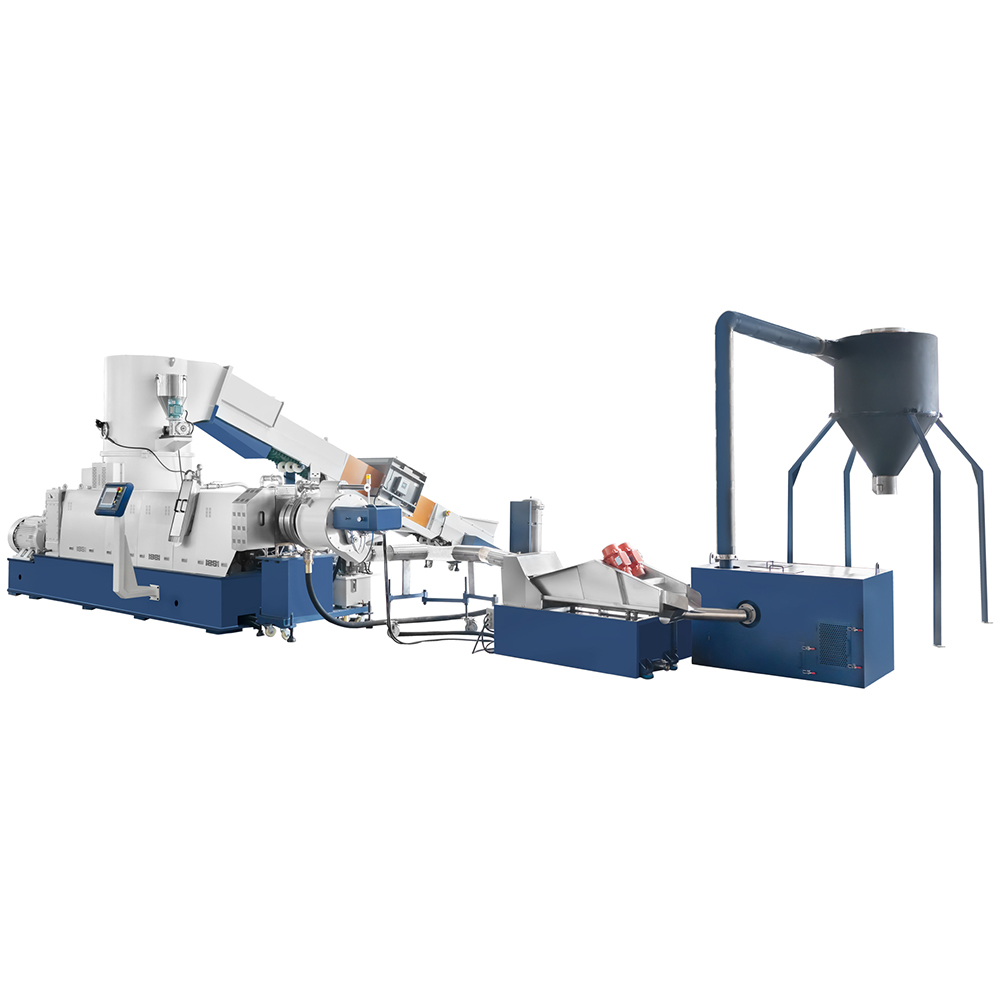

PP PE Film Recycling Extruder Machine with Shredding Agglomerator

With tiny metal get broken screw and barrel easily, many customer request for

Belt conveyor get inter-lock with shredding compactor. Once compactor inner temperature go high too much, and its ampere go increase too much, belt conveyor get stopped automatically.

Compactor cutter valve, which can monitoring the material feeding speed with avoiding melted compactor. That design do great help for balance cutting.

Double vacuum degassing system which can exhaust the gas and water at large extent.

Various hydraulic filtering system ensure large filtering screen for impurity. Stable pressure and fast screen changing speed.

Cutting system used according to material feature -

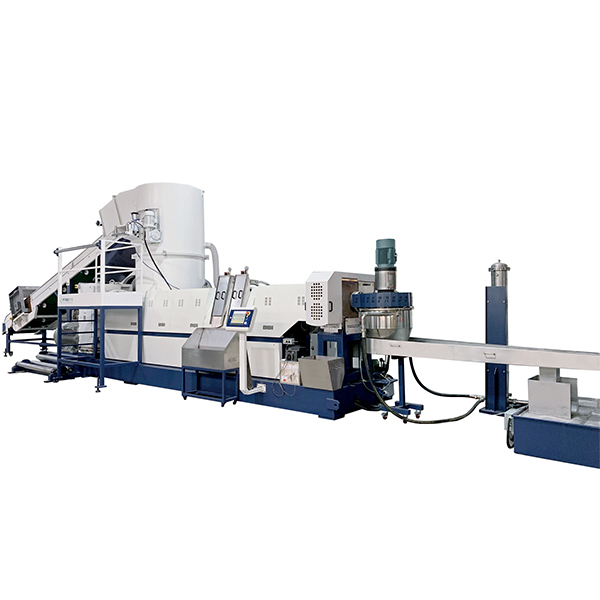

Two stages plastics Film and fibers and bags Pelletizing machine

Easy and automatic control and feed the soft plastics.

Belt conveyor get inter-lock with shredding compactor. Once compactor inner temperature go high too much, and its ampere go increase too much, belt conveyor get stopped automatically.

Compactor cutter valve, which can monitoring the material feeding speed avoiding melted compactor. That design do great help for balance cutting.

Double vacuum degassing system which can exhaust the gas and water vapor at large extent.

Various hydraulic filtering system ensure large filtering screen for impurity. Stable pressure and fast screen changing speed.

Cutting system used according to material feature -

ML Model Single Screw Plastic Recycling Extruder with Cutter Compactor

With tiny metal get broken screw and barrel easily, many customer request for

Belt conveyor get inter-lock with shredding compactor. Once compactor inner temperature go high too much, and its ampere go increase too much, belt conveyor get stopped automatically.

Compactor cutter valve, which can monitoring the material feeding speed with avoiding melted compactor. That design do great help for balance cutting.

Double vacuum degassing system which can exhaust the gas and water at large extent.

Various hydraulic filtering system ensure large filtering screen for impurity. Stable pressure and fast screen changing speed.

Cutting system used according to material feature -

BOPP film granulating machine granulation machine

BOPP film granulation machine is designed to recyle the BOPP post indutrial films and sheets scraps.

-

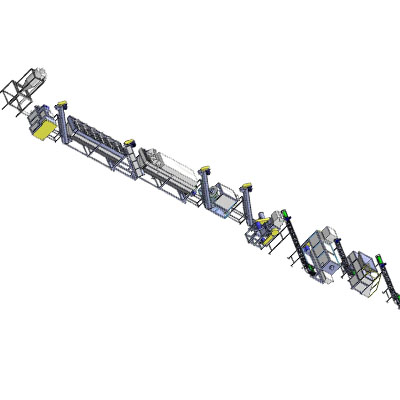

PP Jumbo Bag Crushing Washing Drying Pelletizing Recycling Machine

PP woven jumbo bags are always very dirty and with a lot of residue material. generally, the PP woven jumbo bag is too strong to crush/grind for common crusher machine/granulator,additionally, most of PP woven jumbo bags have a specially strong belt. That is why it is a headache problem for some small factory or company to resolve. we make and design an effective turnkey solutions to handle it easily according to our experience. First, using PP woven jumbo bag’s specially designed double shaft shredder machine to shred the woven bag into big pieces, and then we can use the common PP woven bag scraps washing line and also the PP woven jumbo bag pelletizing line to recycle them directly, finally, we can get the clean,dry PP woven bag scraps or PP repellets.

-

Latest Design Jute Fabric Plastic Yarn Fiber Cutting Machine for Recycling

As a machine to dry the cleaned PP LDPE,HDPE film, the PP woven bags, it provides great help to solve the moisture problem of cleaning materials.

The final moisture is within 3-5% for PE and PE materials. It plays a essential role in the plastic washing line. The end products can be directly to extruded pelletizing.

-

Flexiable Laminated Plastic Film Recycling Extruder

Laminated film recycling machine is designed for reprocessing PE and PP flexible packaging material, printed and non-printed. This cutter integrated Laminated film recycling machine eliminates the need of pre-cutting material, requires less space and energy consumption while producing high quality plastic pellets at a productive rate.

-

PET fiber fabrics pelletizing and recycling machine

It can recycle the most of the soft plastics and some rigid plastics. The soft material contains wholes rolls and crushed PET fibers and films, PET fabrics, LLDPE, LDPE,HDPE,PP,BOPP,CPP from post industrial or post consumer.

-

Lithium-ion battery separator pelletizing machine

Lithium-ion battery separator pelletizing machine

In simple terms, the membrane is a porous plastic film made of basic materials such as PP and PE and additives. Its main role in lithium-ion batteries is to maintain insulation between the positive and negative electrodes as lithium ions shuttle between them to prevent short circuits. Therefore, an important performance index of the film is its heat resistance, which is expressed by its melting point. At present, most film manufacturers in the world use the wet method, that is, the film is stretched with solvent and plasticizer, and then the pores are formed by solvent evaporation. The highest melting point of the wet-process PE lithium-ion battery separator launched by Tonen Chemical in Japan is 170°C.We can also offer the battery separator pelletizing machine. The battery separator mainly are made from the wet method.