-

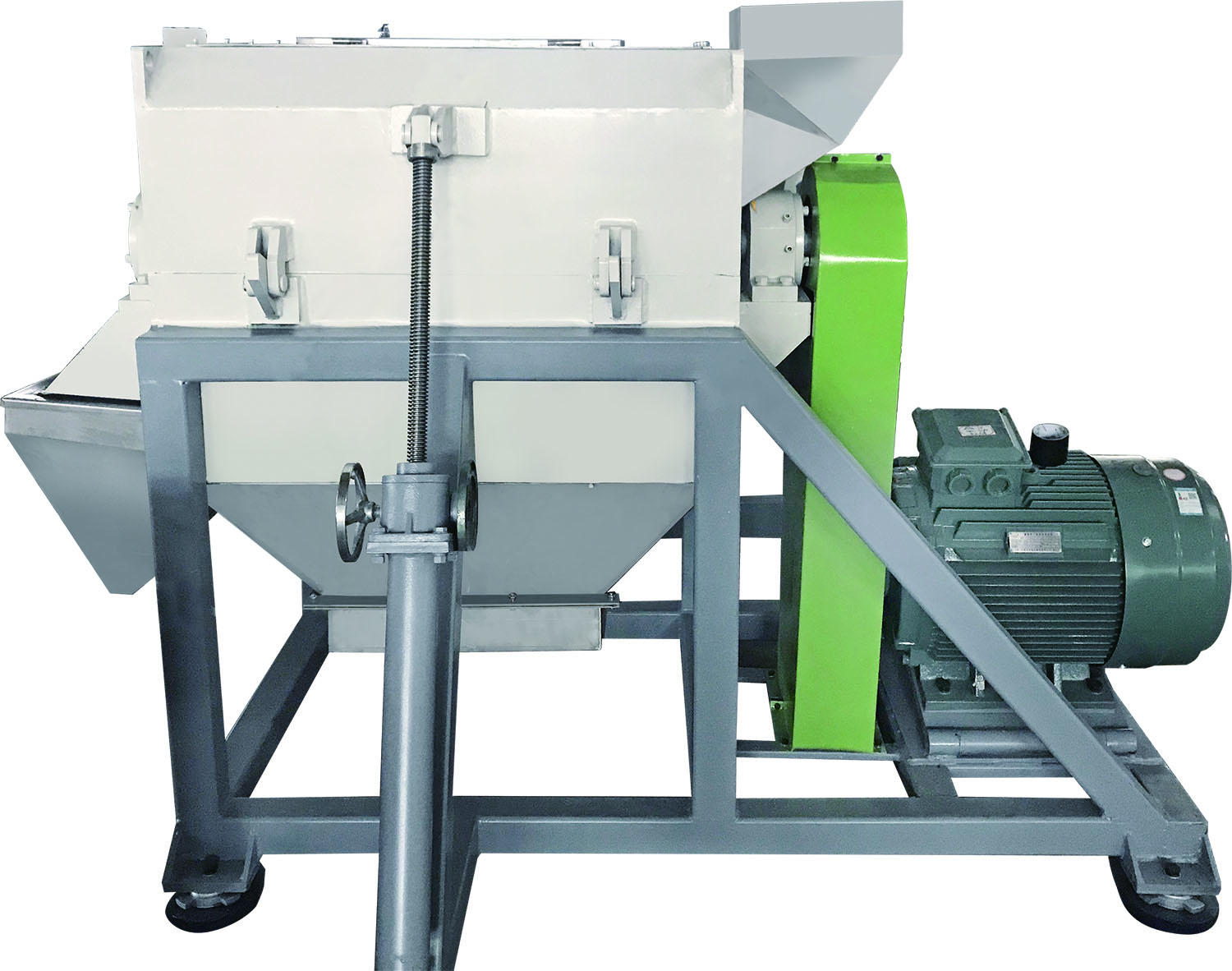

Plastic Crusher for PP PE films and HDPE bottles

Plastic crusher machine for reduce the size of the plastics, such as the PE agriculture films, banana films and bags, PP films, PPwoven bags etc.

-

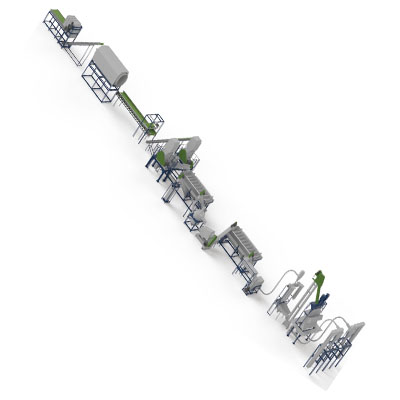

PP Jumbo bag Shredding Crushing Washing Drying Pelletizing Recycling Machine

PURUI Recycling Machine Process Material: Washing line can be used for PP woven bag, film and PE trash bag, film, packing material and some other loose material, agriculture film (1mm), industrial LDPE film with milk and powder, LDPE green- house film. Food packaging film, agriculture film, green house using film, film used in oil field, PP bag, PE film, PP woven bag, LDPE shrink film, multiple film, nature film or heavy printed film, cement bag, oily bag, dirty bag PURUI Recycling Mac... -

Low price for Plastic Recycling Machine /Pet Bottle Flakes Crushing and Washing Production Line

PET bottles washing line we accumulated much experience from the actual project for our customers from all over the world.

In India and homeland we have designed the complete lines for customers recycling the PET bottles. According to customers requirement, we can add or remove some specific machines to reach the target.

-

High definition Factory Wholesale Film Machine PP PE LDPE Plastic Line Pet Bottle Crushing Washing Drying Recycling with Manufacturer Price

PET bottles washing line we accumulated much experience from the actual project for our customers from all over the world.

In India and homeland we have designed the complete lines for customers recycling the PET bottles. According to customers requirement, we can add or remove some specific machines to reach the target.

-

New Vertical raw material transfer machine for plastics films washing friction washing and dewatering machine

New Vertical raw material transfer machine for plastics films washing friction washing and dewatering machine

Three function in one in the plastic PP PE films washing line

Friction washing

Dewatering machine

vertical raw material transfering machine

-

PP/HDPE /PS/ABS Plastic Waste Recycling Washing Machine

plastic washing machine for ABS/PS/PP home appliance housing, electronic waste, factory plastic,

In the field of HDPE/PP/PS/ABS/PC/PET recycling projects. Most of the materials come from urban and industrial collection sites,their sizes vary, and the composition of raw materials is different from country to country, even though the composition of HDPE/PP/PS/ABS/PC/PET in the same country is totally different.

-

plastic washing line for PET bottle/HDPE /industrial films/irrigation pipe

plastic washing line for PET bottle/HDPE /industrial films/irrigation pipe

with advanced PET bottle recycling and cleaning, ensuring the production of superior- quality recycled PET flakes. by leveraging our understanding of the unique attributes of PET bottle bales .

-

Top Grade PP PE Flakes Washing Machine Floating Washer Tank For Plastic Recycling Washing Line

PP PE Flakes Washing Machine Floating Washer Tank For Plastic Recycling Washing Line. This RIGID PE PP PLASTIC WASHING LINE is used to recycling the waste HDPE/LDPE/PP bottles and buckets, hollow container and so on.

The whole recycling line including the conveyor belt, metal detector, wet crusher, floating washing tank, high speed friction washer machine, centrifugal dewatering machine, hot air drying system and material collecting packing system.

The waste dirty rigid PE PP bottles/buckets go through crushing, washing, drying, collecting process will turn to be clean flakes for further pelletizing.

-

Plastic single shaft shredder with pusher for shred PP and PE

The single shaft shredder work as a auxiliary machine for the plastic pelletizing, plastic washing line recycling system. Its function is to reduce the raw materials sizes. For example the plastics like PET fiber, PP woven bags ton bags and PP nonwoven bags, PE agriculture films processing, we need the single shaft to reduce theirs sizes.

-

Intensive Washer/ Centrifugal Dryer-plastic washing line

Intensive Washer/ Centrifugal Dryer

Intensive Washer/Centrifugal dryer is used for cleaning of material, primarily for film flakes, granulat from PET bottles and other rigid types of plastics. The material – if cut with a wet granulator – is extremely wet and fed into the upper hopper, which is located on the edge of the dryer housing. An additional nozzle for spraying-in additional water is available as an option. The rotor transports the material through the dryer from the inlet side to the outlet port. The rotor and the screen configuration combined with the rotary speed determine the cleaning efficiency and the residual moisture content of the material.

-

HDPE bottles detergent bottles and milk bottles washing line simple line plastic recycling machine

The HDPE bottles washing machine can used in recycling the HDPE milk bottles recycling, HDPE detergent bottles washing line, HDPE insecticide bottles recycling. It can be customized according to customer requirements. We will give best solutions to reach customer expectation.

-

PET bottle flakes washing line

PET bottles washing line we accumulated much experience from the actual project for our customers from all over the world, India and Romania etc.

In India and Romania we have designed the complete PET bottle recycle lines for customers. According to customers requirement and raw material condition, we can add or remove some specific machines to reach the target.