China Wholesale Plastic Separator Pricelist – SJ type pelletizing machine for PP PE rigid plastics and squeezed plastics – Purui

China Wholesale Plastic Separator Pricelist – SJ type pelletizing machine for PP PE rigid plastics and squeezed plastics – Purui Detail:

Video:

General information:

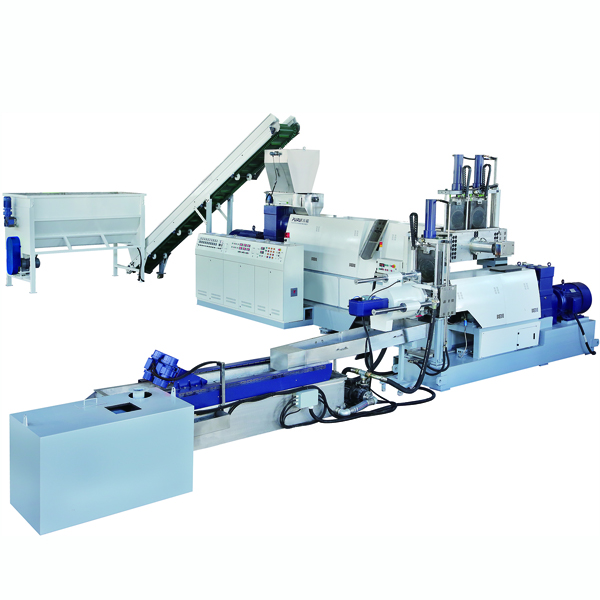

SJ pelletizing machine is mainly for the rigid plastics recycling, such as the crushed or regrind PE, PP, PS, ABS, PC,PA6 etc. Those rigid plastics comes from household appliances, HDPE drums for oil and fuel, HDPE milk bottles, detergent and shampoo bottles, etc. It can also recycle the washed and squeesed dry PE, PP films and soft plastics.

Application:

l Crushed or regrind PE, PP, PS, ABS, PC,PA6

l Squeezed washed PP and PE films.

Features:

1.Two times filtering will guarantee the pellets quality. The filtering mesh size the first stage can use 60mesh. The second stage filtering mesh will be 80-100mesh.

2.Great vacuum degassing system. We use the watering vacuum pump in the pelletizing line. The exhausted gas extract from the extruder and goes into water cylinder for filtering.

3.The screw design is specialized to specific materials.

4.The heaters we used in the barrel is best and reliable in China with long service time.

5.Pelletizing method is optional. The watering pelletizing is suitable for PP and PE films, while for the strand pelletizing it can be used in PP PE and PC and ABS and PA. Also the underwater pelletizing will be universal. All pelletizing method will be easy to maintain and long service time.

6.Good motor brands and qualified high torque gearbox. We use the China best brand motors, Dazhong,and the WEG with UL certification, ABB motors, and Siemens motors optional. Electric parts use the the international brand Schneider or Siemens. Temperature control OMRON. Siemens PLC control is available. Good electric protection method in the machine.

7.Nice design for the safety and usage in plant. We have strict quality control.

We have been in this plastic pelletiizng field for more than 16 years exporting to more than 80 countries all over the world. With much experience and technology workers to solve your plastic recycling machine.

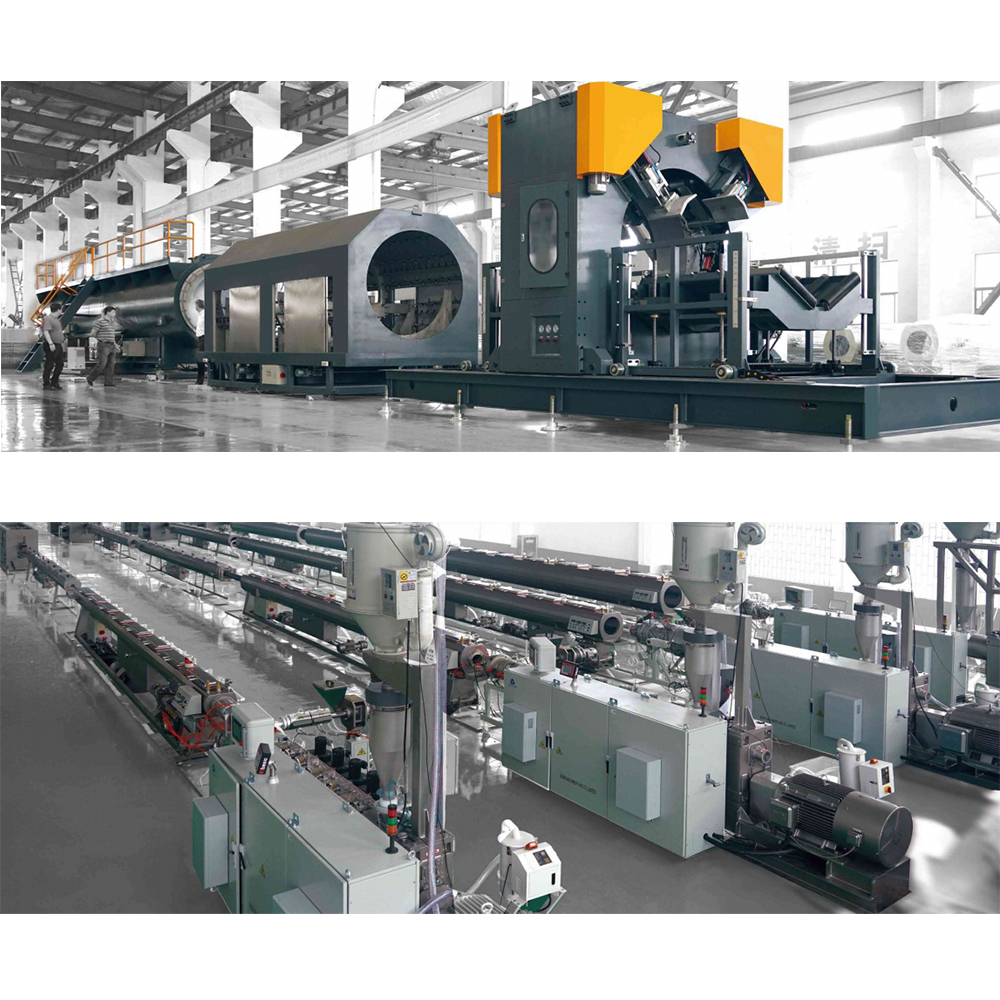

Product detail pictures:

Related Product Guide:

We emphasize development and introduce new products into the market every year for China Wholesale Plastic Separator Pricelist – SJ type pelletizing machine for PP PE rigid plastics and squeezed plastics – Purui , The product will supply to all over the world, such as: Guyana, Indonesia, Nairobi, Actually need to any of those objects be of interest to you, make sure you allow us to know. We'll be delighted to present you a quotation on receipt of one's comprehensive specs. We've our individual specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

Lithium battery recycling equipment is a type of equipment used to recycle and recover valuable materials from lithium-ion batteries, which are commonly used in electronic devices such as smartphones, laptops, and electric vehicles. The equipment typically works by breaking down the batteries into their constituent parts, such as the cathode and anode materials, electrolyte solution, and metal foils, and then separating and purifying these materials for reuse.

There are different types of lithium battery recycling equipment available, including pyrometallurgical processes, hydrometallurgical processes, and mechanical processes. Pyrometallurgical processes involve high-temperature processing of the batteries to recover metals such as copper, nickel, and cobalt. Hydrometallurgical processes use chemical solutions to dissolve the battery components and recover metals, while mechanical processes involve shredding and milling the batteries to separate the materials.

Lithium battery recycling equipment is important for reducing the environmental impact of battery disposal and conserving resources by recovering valuable metals and materials that can be reused in new batteries or other products.

In addition to environmental and resource conservation benefits, lithium battery recycling equipment also has economic benefits. Recovering valuable metals and materials from used batteries can reduce the cost of producing new batteries, as well as create new revenue streams for companies involved in the recycling process.

Furthermore, the increasing demand for electric vehicles and other electronic devices is driving the need for a more efficient and sustainable battery recycling industry. Lithium battery recycling equipment can help meet this demand by providing a reliable and cost-effective way to recover valuable materials from used batteries.

However, it’s important to note that lithium battery recycling is still a relatively new industry, and there are challenges to overcome in terms of developing efficient and cost-effective recycling processes. Additionally, proper handling and disposal of battery waste is crucial to avoid environmental and health hazards. Therefore, proper regulations and safety measures must be in place to ensure the responsible handling and recycling of lithium batteries.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!