Gantry Pelletizer and strand pelletizing machine for plastics PP PE ABS PA6 PC

Gantry Pelletizer for plastics PP PE ABS PA6 PC

Gantry pelletizer are suitable for cold drawn strip pelletizing of various thermoplastic general engineering plastics and modified engineering plastics, such as ABS, PA, PBT, PC, PE, PET POM, PP, PPS, PVC, SAN, etc. . This includes pelletizing basic strips such as glass fiber reinforced and inorganic-filled thermoplastics. It can be used with various small and mediumsized, single and twin screw extruders. The material bar is cooled by the cooling water tank,pass the cooling conveyor belt, enter into the air dryer, and then enters the feed port of the pelletizer. There are traction rollers for forcedly feeding between the fixed knife and the movable knife to make the pellets.

It has the below characteristics:

1. Both sides of the cutter support to make press evenly and have good stability

2. Fast traction speed and high production efficiency

3.High precision of moving knife rotation, beautiful cutting shape and less cutting powder

4.Replace the rubber pressure roller quickly, the replacement time is less than 5min

5.Quickly replace the movable knife assembly, the replacement time is less than 30min

6.Quickly replace the traction roller assembly, the replacement time is less than 30min

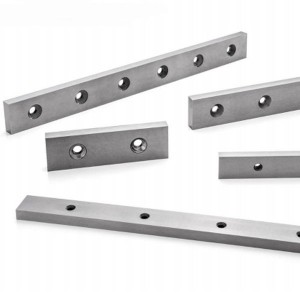

7.The blade is sharp, the pellet is beautiful, and the use time is long

8.Equipped with imported bearings, long service life

9.Equipped with soundproof cover to reduce working noise

10.Equipped with high-quality casters, long service life

11.TPS series is equipped with high-quality accessories, high reliability and long service life

12.The APS series is a low-cost configuration that does not reduce the pelletizing performance, and improves the cost performance

13.With open cover chain safety protection

14.Simple operation, easy to clean, easy to disassemble, easy to install

15.The motor is installed in the lower part, which increases the weight of the bottom, it is convenient to move, safe and reliable

Capacity:

|

Model |

APS/TPS100 |

APS/TPS150 |

APS200/TPS200 |

APS300/TPS300 |

|

Capacity Kg/h |

150/300 |

500/600 |

800/1000 |

1500/1500 |

For any enquiry, please contact us freely.

Contact person:Aileen.he@puruien.com

Email: aileen.he@puruien.com

Mobile:0086 15602292676(whatsapp and wechat)

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.