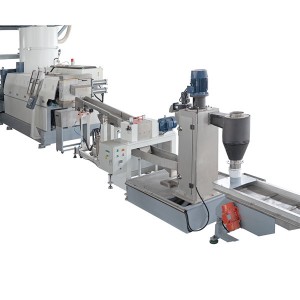

PET fiber fabrics pelletizing and recycling machine

PET fiber fabrics pelletizing and recycling machine

The special designed PET fiber fabrics pelletizing is to recycle the most of the soft plastics and some rigid plastics. The soft material contains wholes rolls and crushed PET fibers and films, PET fabrics, LLDPE, LDPE,HDPE,PP,BOPP,CPP from post industrial or post consumer.

Considering the materials' characteristics, for some post-industrial materials we recommend the single stages pelletizing system. For example the the BOPP films, PET fibers from water jet weaving selvedges, POY discards and DTY discards etc. Considering the regrind pellets will be used for making the new films or fibers, we improve the filtering system. For example we add two filters on the single screw for filtering more smaller fines. The final mesh could reach 200 mesh. In the middel we add one melt pump to increase melt pressure ensure the melted raw material get into the second filter for fine filtering. It will not only increase the pellets quality but also increase the pellets quality.

Apart from the filtering system, we make some improvement on the cutter compactor to add one dehumifying system, it will largely decrease the moisture content of the raw materials.

Finally we will have the under water strand pelletizing to make the strand easy to feed into the pelletizer. It will save the manual work comparing the dry strand pelletizing.

|

Model |

ML85 |

ML100 |

ML130 |

ML160 |

ML180 |

|

Output(kg/h) |

120-180 |

200-350 |

400-500 |

600-800 |

800-1000 |

|

Model |

ML85B |

ML100B |

ML130B |

ML160B |

ML180B |

|

Output(kg/h) |

200-350 |

350-450 |

500-600 |

800-900 |

900-1100 |

We have been in the plastic recycling machine for more than 15 years. Exporting to more than 70 countries, with good after sale service and reputation. We will continue to serve our customers and offer the best quality machines.

For any enquiry, please contact us freely.

Contact person:Aileen.he@puruien.com

Email: aileen.he@puruien.com

Mobile:0086 15602292676(whatsapp and wechat)

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

Lithium battery recycling equipment is a type of equipment used to recycle and recover valuable materials from lithium-ion batteries, which are commonly used in electronic devices such as smartphones, laptops, and electric vehicles. The equipment typically works by breaking down the batteries into their constituent parts, such as the cathode and anode materials, electrolyte solution, and metal foils, and then separating and purifying these materials for reuse.

There are different types of lithium battery recycling equipment available, including pyrometallurgical processes, hydrometallurgical processes, and mechanical processes. Pyrometallurgical processes involve high-temperature processing of the batteries to recover metals such as copper, nickel, and cobalt. Hydrometallurgical processes use chemical solutions to dissolve the battery components and recover metals, while mechanical processes involve shredding and milling the batteries to separate the materials.

Lithium battery recycling equipment is important for reducing the environmental impact of battery disposal and conserving resources by recovering valuable metals and materials that can be reused in new batteries or other products.

In addition to environmental and resource conservation benefits, lithium battery recycling equipment also has economic benefits. Recovering valuable metals and materials from used batteries can reduce the cost of producing new batteries, as well as create new revenue streams for companies involved in the recycling process.

Furthermore, the increasing demand for electric vehicles and other electronic devices is driving the need for a more efficient and sustainable battery recycling industry. Lithium battery recycling equipment can help meet this demand by providing a reliable and cost-effective way to recover valuable materials from used batteries.

However, it’s important to note that lithium battery recycling is still a relatively new industry, and there are challenges to overcome in terms of developing efficient and cost-effective recycling processes. Additionally, proper handling and disposal of battery waste is crucial to avoid environmental and health hazards. Therefore, proper regulations and safety measures must be in place to ensure the responsible handling and recycling of lithium batteries.