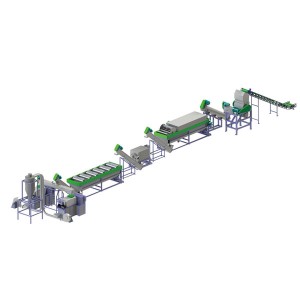

Trommels Can be integrated to new or existing plants For waste management and recycling facilities

A trommel is a cylindrical drum-like machine used in various industries for sorting and separating materials. Such as in waste management and recycling facilities for sorting and separating waste plastics. It consists of a rotating drum that is usually perforated or meshed, allowing smaller particles to pass through while larger materials are retained.

Material Feeding: Waste plastic materials are fed into the trommel, usually through a hopper or conveyor belt. This can include a variety of plastic items such as bottles, containers, packaging, and other plastic waste.

Rotating Drum: The trommel drum rotates, typically driven by an electric motor. The drum is perforated or fitted with mesh screens of different sizes, allowing for the separation of plastics based on their dimensions.

Separation by Size: As the drum rotates, smaller plastic particles, such as plastic flakes or granules, pass through the perforations or mesh screens, while larger items, such as plastic bottles or containers, are retained inside the drum.

Material Sorting: The smaller plastic particles that pass through the trommel are typically directed towards further processing steps, such as washing, shredding, or pelletizing. These processes help prepare the plastic for recycling into new products.

Discharge: The larger plastic items that remain in the trommel drum are typically discharged at the end of the process. They can be manually sorted or further processed to remove contaminants before being sent for recycling or disposal.

Trommels used in waste plastic applications can be customized with specific drum perforations or mesh screens to accommodate different types and sizes of plastic waste. They are an effective tool for separating plastic materials based on their size, allowing for efficient recycling and resource recovery.

video:

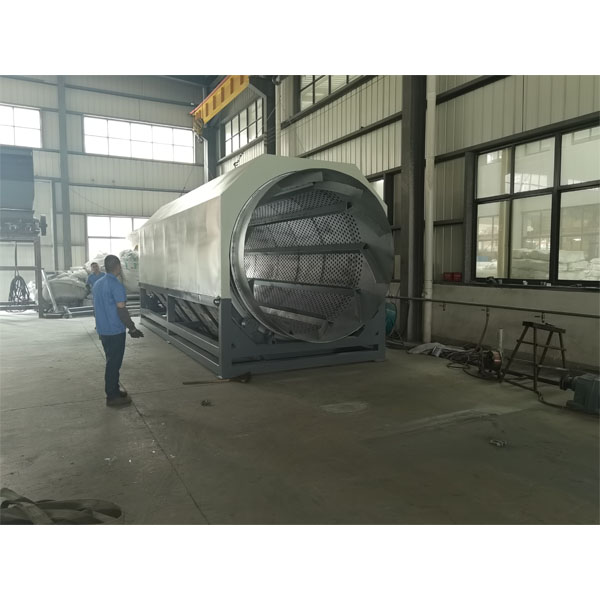

A plastic recycling and granulating machine is a type of equipment used to recycle plastic waste into granules or pellets that can be reused in manufacturing new plastic products. The machine typically works by shredding or grinding the plastic waste into small pieces, then melting and extruding it through a die to form pellets or granules.

There are different types of plastic recycling and granulating machines available, including single-screw and twin-screw extruders. Some machines also include additional features such as screens to remove impurities from the plastic waste or cooling systems to ensure the pellets are solidified properly. PET bottle washing machine, PP woven bags washing line

Plastic recycling and granulating machines are commonly used in industries that generate large amounts of plastic waste, such as packaging, automotive, and construction. By recycling plastic waste, these machines help reduce the environmental impact of plastic disposal and conserve resources by reusing materials that would otherwise be discarded.

Lithium battery recycling equipment is a type of equipment used to recycle and recover valuable materials from lithium-ion batteries, which are commonly used in electronic devices such as smartphones, laptops, and electric vehicles. The equipment typically works by breaking down the batteries into their constituent parts, such as the cathode and anode materials, electrolyte solution, and metal foils, and then separating and purifying these materials for reuse.

There are different types of lithium battery recycling equipment available, including pyrometallurgical processes, hydrometallurgical processes, and mechanical processes. Pyrometallurgical processes involve high-temperature processing of the batteries to recover metals such as copper, nickel, and cobalt. Hydrometallurgical processes use chemical solutions to dissolve the battery components and recover metals, while mechanical processes involve shredding and milling the batteries to separate the materials.

Lithium battery recycling equipment is important for reducing the environmental impact of battery disposal and conserving resources by recovering valuable metals and materials that can be reused in new batteries or other products.

In addition to environmental and resource conservation benefits, lithium battery recycling equipment also has economic benefits. Recovering valuable metals and materials from used batteries can reduce the cost of producing new batteries, as well as create new revenue streams for companies involved in the recycling process.

Furthermore, the increasing demand for electric vehicles and other electronic devices is driving the need for a more efficient and sustainable battery recycling industry. Lithium battery recycling equipment can help meet this demand by providing a reliable and cost-effective way to recover valuable materials from used batteries.

However, it’s important to note that lithium battery recycling is still a relatively new industry, and there are challenges to overcome in terms of developing efficient and cost-effective recycling processes. Additionally, proper handling and disposal of battery waste is crucial to avoid environmental and health hazards. Therefore, proper regulations and safety measures must be in place to ensure the responsible handling and recycling of lithium batteries.